Beschrijving

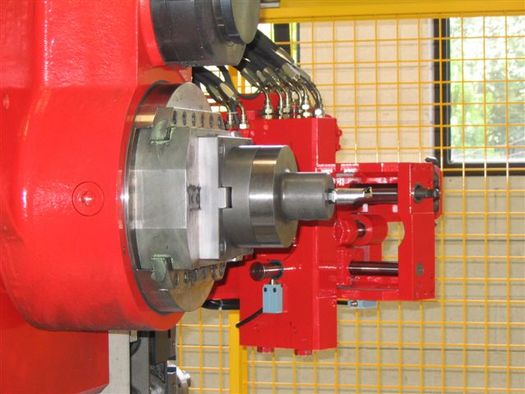

The DS900/300C machining centre features n. 2 machining systems:

1) Turning head with n. 2 tool-holder posts on mobile carriage, so as to perform small as well as large diameter turning operations with the same tool;

2) Fast spindle fitted underneath the turning head, suited for drilling, tapping and other operations at high revolution rates.

This ruggedly constructed machine is designed to include an excellent chip disposal system and a totally sealed onboard-mounted enclosure, insuring no release of fluid / chips.

All mechanical moving organs of the machine head are made of treated steel and are lubricated by an exclusive oil circuit.

The base frame is made of electro-welded, stabilized steel.

The head is made of Meehanite cast iron.

All axes slide on cross-roller guide shoes and are actuated by ball screws with pre-loaded, double lead screw and Brushless motors.

The mechanical organs of the turning head are of sturdy construction, so as to guarantee heavy removal with utmost reliability.

The machine CNC governs all movements.

During the facing operation, the tool works at its best, being controlled by a constant-cut machining program.

The fast spindle protrudes from underneath the turning head only when the latter is clamped.

The rotary, 360.000 stepless indexing table is equipped with guideways and devices designed to accommodate the tool-holder pallets.

The DS900/300C machining centre is equipped with a tool-changer unit located vertically on the column side, fitted with a 2-gripper tool-changer manipulator.

| Turning diameter | max. | 350mm |

| Travel of facing head | 70 mm | |

| Maximum facing head rpm | 450 | |

| Travel of axis. | ||

| X axis | mm | 680 |

| Y axis | mm | 520 |

| Z axis | mm | 600 |

| B axis | degrees | 36.000 |

| U 1 - axis | mm | 70 |

| U 2 – axis for small diameters with high rpm from ATC | mm | 30 |

| Trust on axis . | ||

| X axis | 2.580 kg | |

| Y axis | 2.580 kg | |

| Z axis | 2.580 kg | |

| Working tables. | ||

| Pallet sizes | 600 x 600 | |

| Weight on pallet | 900 kg | |

| Table torque | max. | 1.300 Nm |

| Swing on pallet | max. | 800 mm |

| ATC. | ||

| Tool magazine | positions stand. | 46 [90] |

| Tool length | max. stand. | 480 mm |

| Tool weight | max. stand. | 25 kg |

| The spindle headstock with 2 stations: | ||

| 1st station: | ||

| Turning disc with facing head, | diameter | 300 mm |

| travel | 70 mm. | |

| Spindle motor power | 18,5 kW | |

| RPM (constant power) from | 250 to 750 rpm | |

| Max. torque | 700 Nm | |

| Spindle bearing diameter | 280 mm | |

| 2nd station: | ||

| Work axis fitted with fast spindle | ||

| Spindle motor power | 18,5 kW | |

| Number of ranges | 2 | |

| Torque | max. | 700 Nm |

| Constant power | 750- 3.000 rpm. |